3D printing has been around for a while, but the global development community is only recently exploring how it can be used for social change. From printing low-cost prosthetics to providing basic supplies after a disaster, 3D printing’s potential to benefit society is undeniable. These were the kind of topics we set out to explore with participants from 10 different countries in TechChange’s first 3D Printing for Social Good online course.

We started the course with a deep dive into 3D printing, examining how it works, how it can be used, and the tech ecosystem in which it exists. We enlisted the help of guest experts like Jeremy Simon of 3D Universe and Colin McCormick, who brought us a live 3D printing demo. Course participants also had the opportunity to learn more about free CAD tools and practice creating digital 3D models of objects, as well as find a makerspace or Fab Lab near them.

Then we examined how 3D printing is being used for social good through the work of e-NABLE, techfortrade, and Field Ready, and course participants had the opportunity to interact with key stakeholders in each organization. Based on the insights from our sessions with e-NABLE’s founder Jon Schull, Matthew Rogge of techfortrade, and co-founder of Field Ready, Dara Dotz, participants discussed the potential for adapting the models of these organizations to create change in their own contexts.

Finally, we focused on the challenges and opportunities in 3D printing for social good. In particular, we learned how 3D printing fits into the larger Maker Movement and explored how the methods, mindsets, and tools adopted by the Maker Movement could be leveraged for social good with the help of guest experts Robert Ryan-Silva of DAI Maker Lab and Kate Gage of USAID Global Development Lab.

Here’s a recap of our guest expert sessions:

- Gabriel Krieshok of the US Peace Corps spoke from his experience implementing technology solutions and shared his excitement about the potential that 3D printing holds for underserved populations living in low-resource settings.

- Jeremy Simon of 3D Universe shared his experience with a variety of 3D printing technologies and demonstrated the power of 3D printing on a personal level by discussing projects he has worked on with his family and the e-NABLE community.

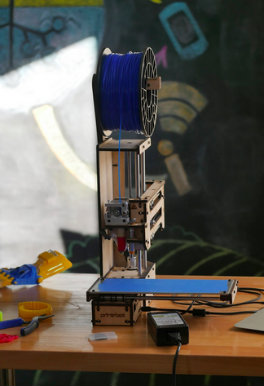

Sara and Colin, during the 3D printing demo

- Colin McCormick brought us a live 3D printing demo, walking us through the process of finding, modifying and printing an object from a digital 3D model he found online. In addition, he described his experience building a 3D printer from a DIY kit.

- Matthew Rogge of techfortrade explained the work that he’s doing in Latin America with ethical filament, and in East Africa with 3D printers made from e-waste. Through both of these projects, techfortrade is using locally-sourced materials that are available in abundance to improve livelihoods and increase access to 3D printing technology.

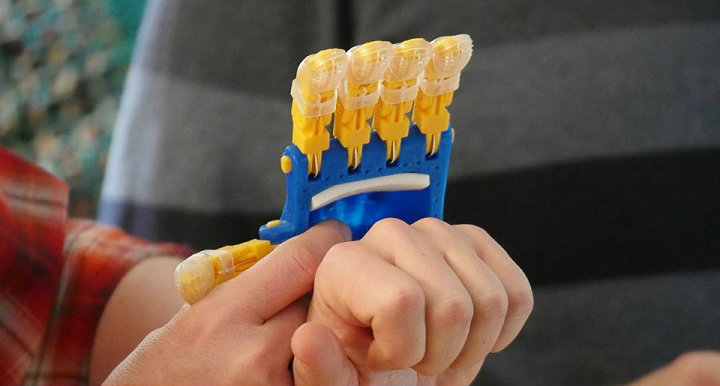

- Jon Schull, founder of e-NABLE, provided insight into e-NABLE’s crowdsourced model for providing low-cost prosthetic devices to people in need, and the future of the e-NABLE Community Foundation.

- Dara Dotz, co-founder of Field Ready spoke about her experience 3D printing in extreme environments, from implementing Field Ready’s pilot program to 3D printing medical supplies in Haiti, to designing a 3D printer used in the International Space Station with ‘Made in Space’. Dara demonstrated how 3D printing can disrupt the supply chain in both extremes by dramatically reducing costs and the time it takes to access or produce parts; recycling, reusing and reprinting parts; and prototyping and producing tools from waste.

- Robert Ryan-Silva of DAI Maker Lab talked about how increasing access to maker tools, such as 3D printing, CNC tools, and electronic building blocks, can help people create, champion, and iterate upon solutions that meet their needs, in their own context.

- Kate Gage of the USAID Global Development Lab provided examples of innovative solutions that have come out of the Maker Movement. She also stressed the need to create pathways that help makers apply their skills to some of the world’s greatest challenges and create viable, human-centered solutions.

While all the developments in the field of 3D printing are exciting, it is important to understand that implementing 3D printing technology in low-resource settings comes with a few challenges. Limitations like slow print speed, the resilience of 3D printed objects and 3D printers themselves, and access to resources like filament and a steady power supply to complete a 3D print job are important realities to consider when taking 3D printing to low-resource settings.

3D printing technology is advancing at a rapid pace to address some of these limitations. Far greater than the challenges inherent in 3D printing, conversations with guest experts and among course participants, as well as the projects highlighted in this course, have demonstrated the potential that 3D printing holds for social good- from improving healthcare delivery, to creating breakthroughs that can contribute to sustainable global development.

Who are the other players using 3D printing for social good? Or if you own a 3D printer, what are you using it for? Comment below or tweet at us @TechChange

About author

Sara Pitcairn is Co-Director of Instructional Design at TechChange, where she works with clients to develop and design custom online learningexperiences , ranging from webinar series to facilitated and on-demand courses. She is also the facilitator for TechChange’s 3D Printing for Social Good course. Prior to TechChange, Sara taught middle and high school STEM courses at the Barrie School, where she also led an Engineering Product Design program for high school students. Sara graduated from Yale University with a degree in Mechanical Engineering, which sparked her passion for design thinking and human-centered design. In her spare time, Sara enjoys reading, traveling, and perfecting her guacamole recipe.