It may be difficult to see the relevance of 3D Printing beyond maker labs, but its potential to help in international development, and especially humanitarian response should be explored further.

In 2013 alone, there were more than 334 natural disasters around the world resulting in more 100,000 deaths. While the numbers decreased in 2014, in 2015 we are already seeing the devastating effect of the earthquake in Nepal. Not only do natural disasters claim lives, they also disrupt the supply chain, making it difficult for those affected to access basic goods and services. While it may not be applicable in the immediate aftermath of a disaster, 3D printing can help with recovery from a disaster by filling the gap in the supply chain.

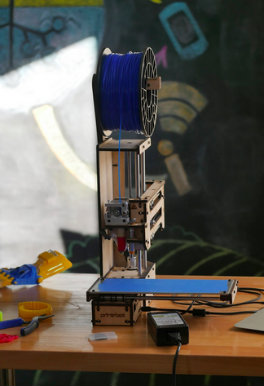

3D printing is changing what you can produce and where you can produce it, making it a solution that could meet the needs of people after a humanitarian crisis.

Here is why:

Low cost

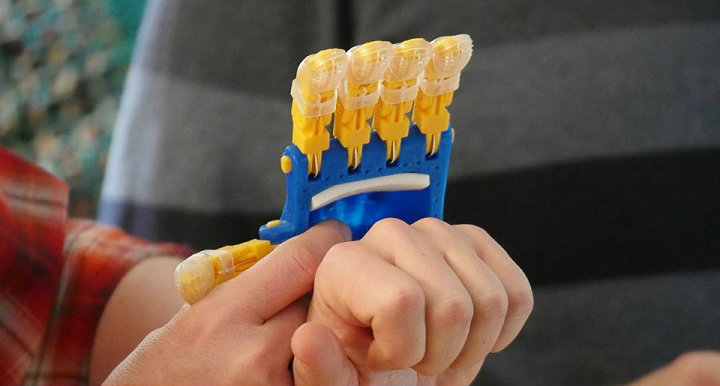

3D printers are no longer out of our reach. As they are becoming more sophisticated and affordable and many patents are expiring, there are now a wide range of consumer 3D printers available for purchase. Field Ready launched a pilot in Haiti where they test-manufactured a variety of umbilical clamps, enough to supply a local clinic for a month. Along with that, they also printed a prosthetic hand, items to repair and improve the printers, butterfly needle holders, screwdrivers, pipe clamps, and bottles. Being able to 3D print medical equipment on site can save costs in purchasing and transporting them from outside, allowing the funds to be used for other important resources that need to be delivered.

Portable

Not only can 3D printers manufacture basic supplies at a low cost, they are also portable so they can be easily transported anywhere there is a need. Many supplies and materials are delivered to disaster affected areas from off-site, creating wait time and possibilities of the supplies getting damaged in transit. It can be a great relief to know that you can print basic necessities like medical tools, or materials to construct a shelter on-site before more permanent supplies are delivered to you.

Immediate correction

Communication can be difficult during a crisis, and sometimes relief delivery of supplies may not fit the requirements of the needs. In this case, it takes more time and money to correct the situation. With a 3D printer, you can immediately change the design of the product you are imagining and test print multiple versions in a short time until you end up with your desired final product.

While the solutions may sound exciting, we have to be mindful of the fact that disaster-stricken places may not have resources needed to run 3D printers. Electricity, human capital, and availability of raw materials are just a few potential barriers. So, organizations like Field Ready are exploring solar powered 3D printers and have already tested a basic curriculum to teach locals how to design items and use the printers. While there is more to learn on what is possible with 3D printing, the possibilities it offers for humanitarian response are endless.

We will be exploring topics like this and other ways 3D printing is being used for social good, as well as hear from experts who are already using 3D printers in this context and can see its potential for society, in our upcoming course on 3D Printing for Social Good.

There is still time to apply, so I hope you can join us!